Today’s electrical grid is an interconnected network for delivering electricity from producers to consumers. The electrical grid provides reliable power to millions of homes and businesses, but electrical failures that affect large areas happen regularly due to extreme weather, natural disasters, and human error.

For data centers, outages and failures can be extremely costly. If the fuel is contaminated, the generator may not start when needed, fail to provide the required power load or break down during operation at the most critical time. With no other means of power back up on-site, this could lead to system operational issues and/or a shutdown from 3 – 10 hrs minimum.

For N1 to N4 sites this can lead to:

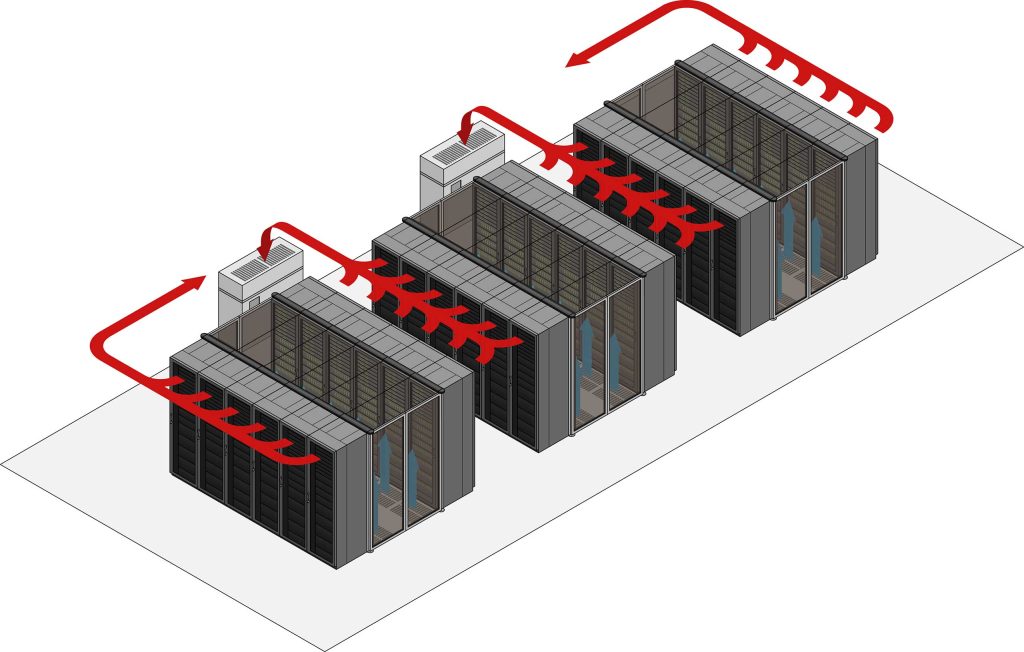

- Data room servers overheating

- Safety issues, having to risk people and equipment to get the site up and running

- Substantial cost from emergency rentals and repairs

- Complete site shut down for days or weeks

- Possible employment loss

- Clients losing their operations

- Contract agreement fees due to operational failure

- Contracts cancelled

- Possible lawsuits

A recent study by the Department of Energy found that financial losses from power outages at data centers ranged from $20,000 to $2 million and up per occurrence.

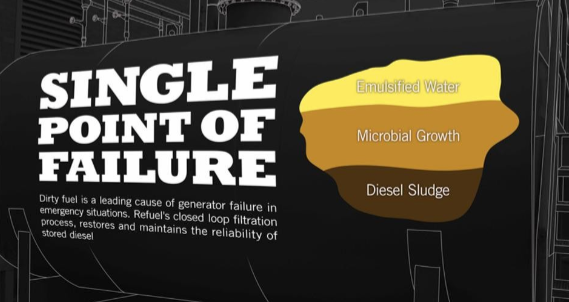

Diesel contamination can occur from many different sources such as transportation chain, temperature changes, storage, handling, and vents. Diesel is not what it was 25 years ago; it has a natural shelf life and is considered an organic. Like all organics, it decays with age. Diesel is also hygroscopic and will absorb moisture from the atmosphere. This process creates emulsified water that is damaging to engines and tanks.

Fuel is a single source of power

Poor fuel quality will lead to a lack of engine performance or cause a shut down that will affect the entire site’s operation.

Fuel can begin to degrade 30 – 120 days, with water and contamination present, this can speed up the process with lead to tremendous damage. Fuel filters can plug and starve the engine of fuel. The filter can also go into by pass. This risks the injection system and engine under performing and/or a possible failure during operations. Contamination will also damage and decrease the tank’s life and reliability, leading to costly repair or replacement.

Proactive fuel service will ensure the fuel is meeting or exceeding OEM and Federal requirements. Eliminating any opportunity of water or contamination that would damage tanks and engines. Ensuring clean and dry fuel when needed most.

CFS is a renowned data center infrastructure company with over 25 years of experience. One of our specialties is in Diesel Fuel Systems and we have partnered up with CleanPower Worldwide as an authorized dealer. Whether in person, or having a meeting over the phone, CFS is confident in our ability to ensure you have a continuously operating data center. Please feel free to give us a call for a complimentary presentation of our Diesel Fuel Systems.