Zinc whisker cleaning

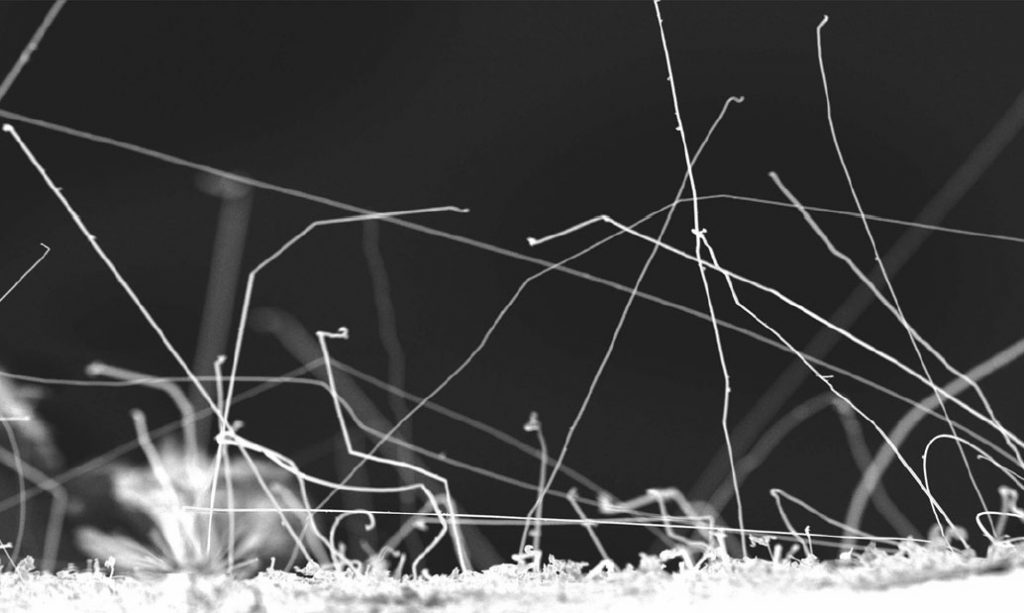

Zinc whisker cleaning is a requirement for any data center that has been determined to have zinc contamination, because zinc whiskers, tiny conductive filaments of zinc typically less than a few millimeters (mm) long and only a few thousandths of a millimeter in diameter, are conductive and will cause electrical shorts.

Here are 6 compelling facts that support zinc whisker cleaning.

- Zinc whiskers were first discovered in 1948 by Bell Labs, when a “whisker” on a zinc-plated bracket caused increased losses in quartz filters used in a telephone transmission system superscript.

- Any zinc-electroplated surface may experience this anomaly, but the products of most concern are certain types of floor tiles used in computer rooms’ raised floor applications. Suspect floor tiles are wood, or wood composite cores, with a flat sheet steel bottom or underside. The steel surface, if passivated using electroplated zinc, can be a major source of contamination. Zinc whiskers have also been found on support braces within server cabinets and support brackets for suspended ceiling systems.

- The main concern is that zinc is a conductive material. A whisker can be considered a low-capacity fuse with DC resistance of 10W to 40W, depending on the whisker geometry, with a DC fusing current of 10mA to 30mA superscript.

- Although the whiskers are small, they are large enough to cause problems in today’s microcircuits such as short circuits, voltage variances, and other signal disturbances. Unexplained loss of power supplies is a main outage caused by zinc whiskers.

- Inspecting for evidence of zinc whiskers is relatively easy but must be done with caution. Pick an area of the data center farthest away from sensitive equipment and air handling equipment and carefully lift a floor tile.

- The only way to successfully deal with zinc whisker contamination is to remove the source. There are short-term cleaning methods that can remove current zinc whisker growth, but the zinc will continue to grow back as long as the zinc producing surface is present. Therefore the cleaning process must be repeated on a regular basis to keep zinc growth at bay. This is a stop-gap, short-term fix and is not a guarantee against zinc related outages. The only way to prevent zinc whisker contamination and outages long-term is to completely remove the source of the zinc growth and clean all zinc growth from the data center.

Do these historical facts help you understand the need for zinc whisker cleaning? Should your data center be examined?